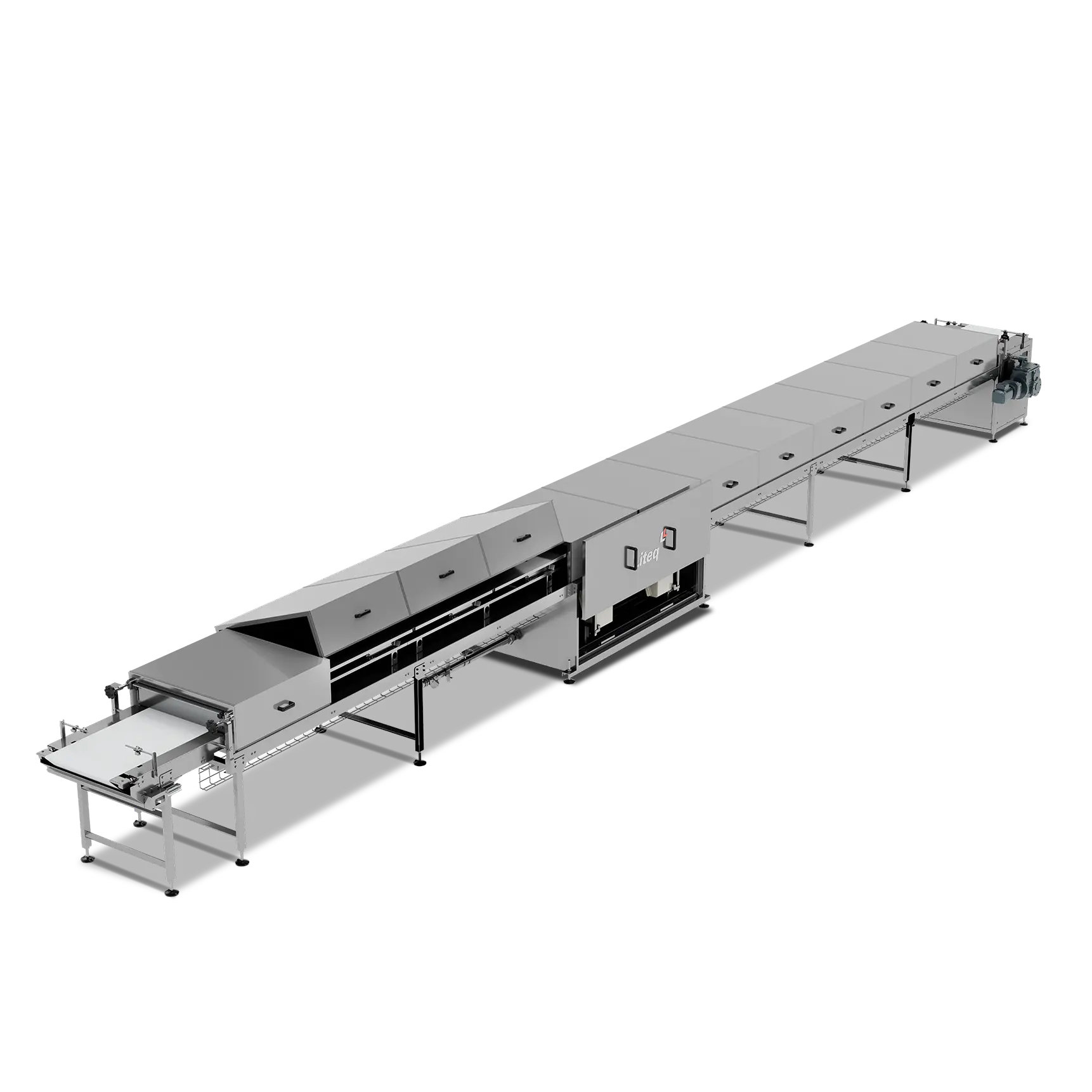

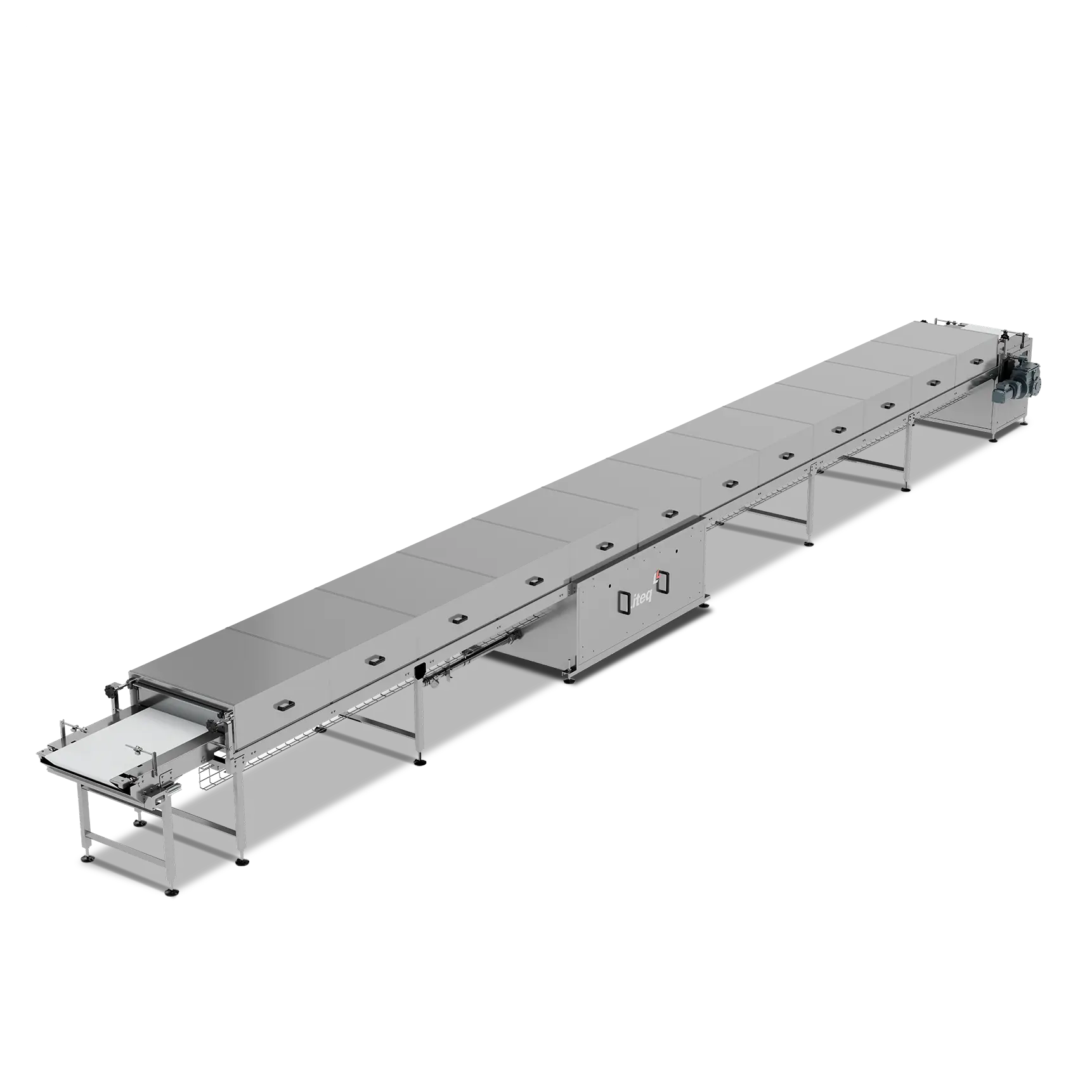

Modular design

with sections

Modular design

with sections

Optimize your production

Cooling tunels

Cooling tunels

LITEQ Cooling Tunnels are specially designed to optimize the cooling of fillings formed from confectionery doughs, cereal bars, crunchy bars, candy interiors, chocolate-covered products and/or similar doughs. These machines have been designed in a modular way, based on 2-meter-long sections that can be 420 to 2,000 mm wide.

Technical details

LITEQ Cooling Tunnels are specially designed to optimize the cooling of fillings formed from confectionery doughs, cereal bars, crunchy bars, candy interiors, chocolate-covered products and/or similar doughs. These machines have been designed in a modular way, based on 2-meter-long sections that can be 420 to 2,000 mm wide. Due to the precision adjustment of their hoods, the tunnel body forms a virtually hermetic whole. Depending on the type of product to be cooled, our equipment can be designed to remove energy by convection, radiation, conduction or a mixture of these techniques.