Chocolate

Chocolate

Tempering

The ideal solution for precise crystallization and superior chocolate quality

Chocolate tempering machines are essential for the production of chocolates, whether molded or coated, because shelf life, product gloss, heat resistance, ease of demoulding, crystallization speed and temperature control...

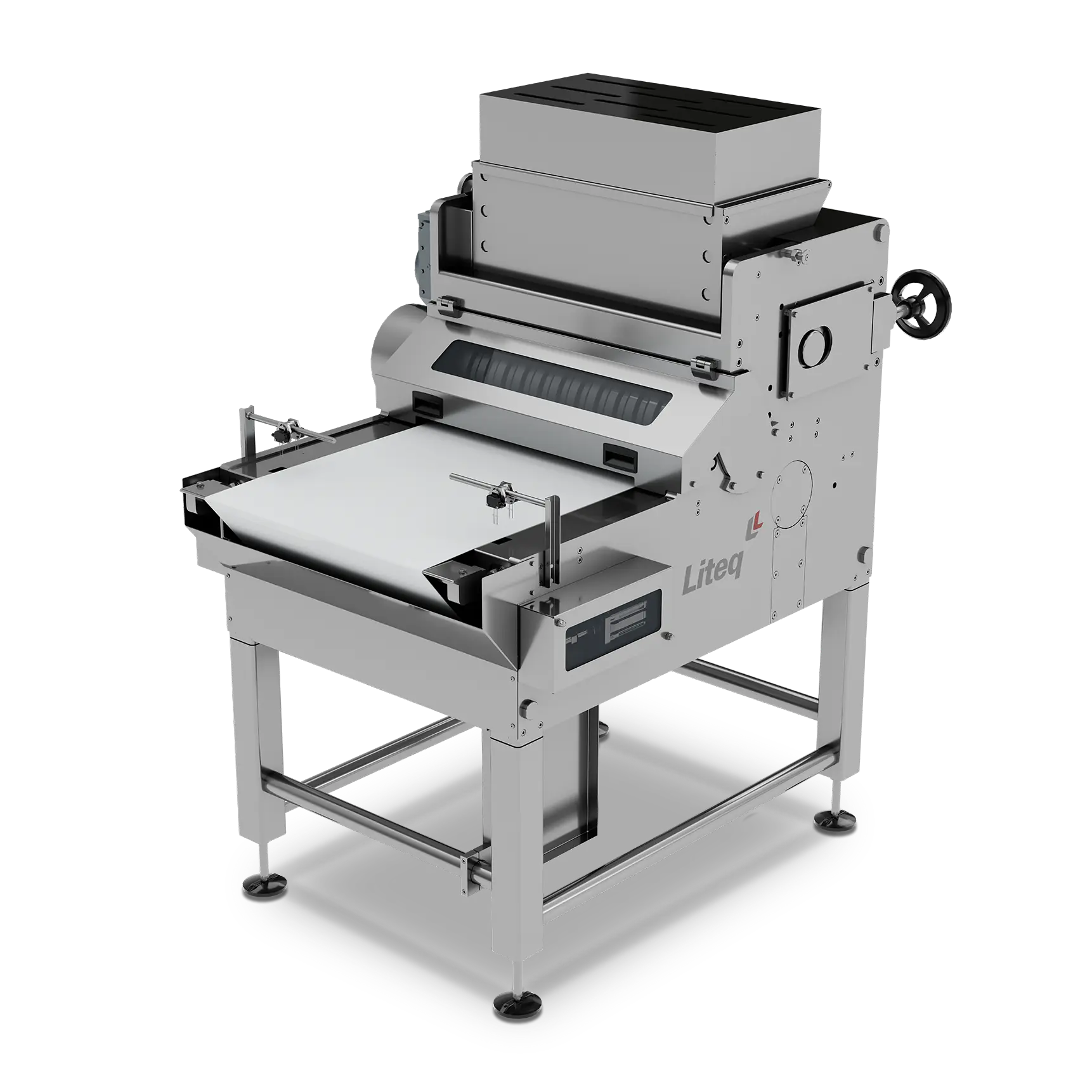

Piston Chocolate Depositor

The ideal solution for precise dosing of chocolates and fillings

The Piston Chocolate Depositor is an extremely versatile and precise piece of equipment, designed to work with the one-shot, point or "tongue" dosing system, which allows it to be used for dosing solid tablets with or without additions, filled chocolates and Easter eggs...

Confectionery

Confectionery

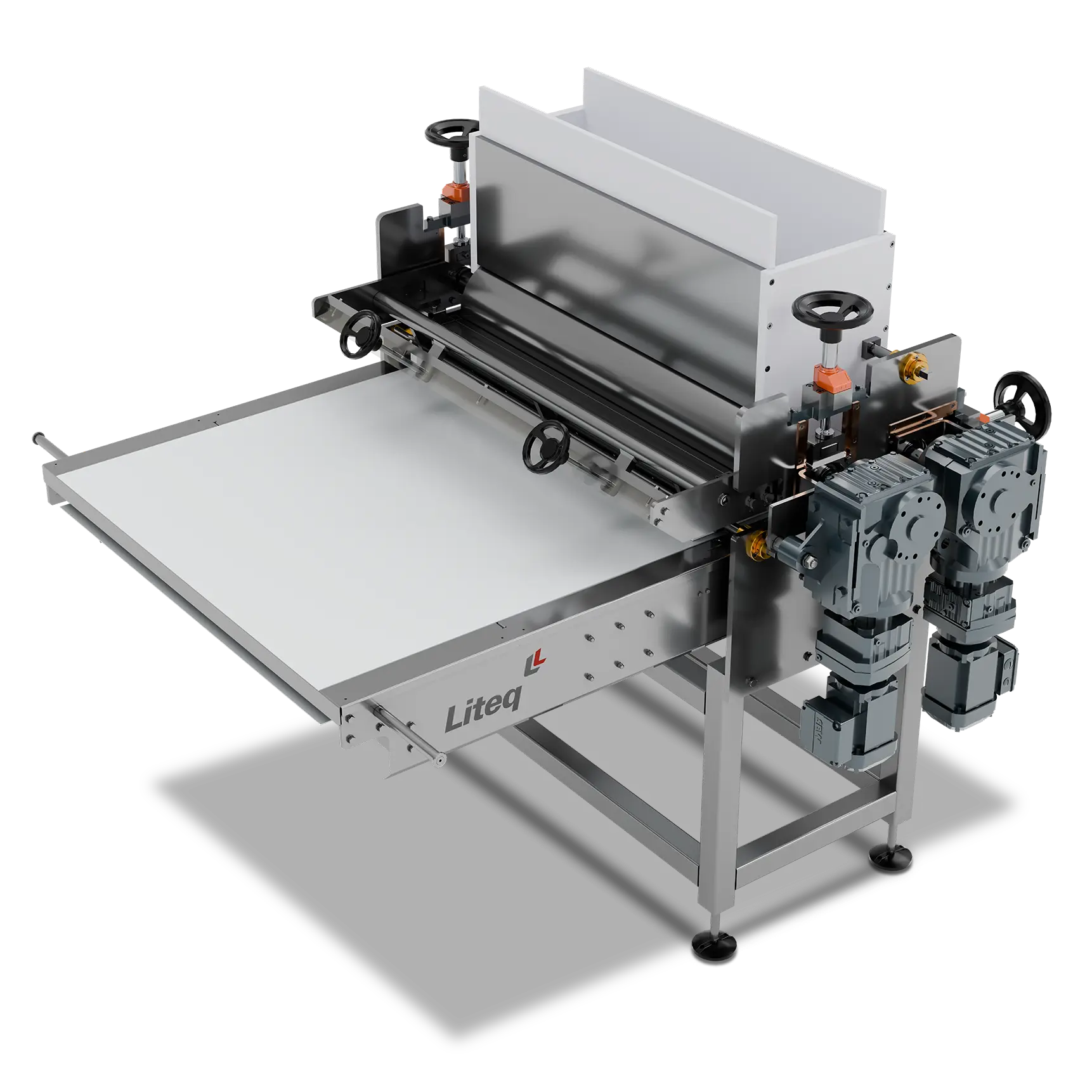

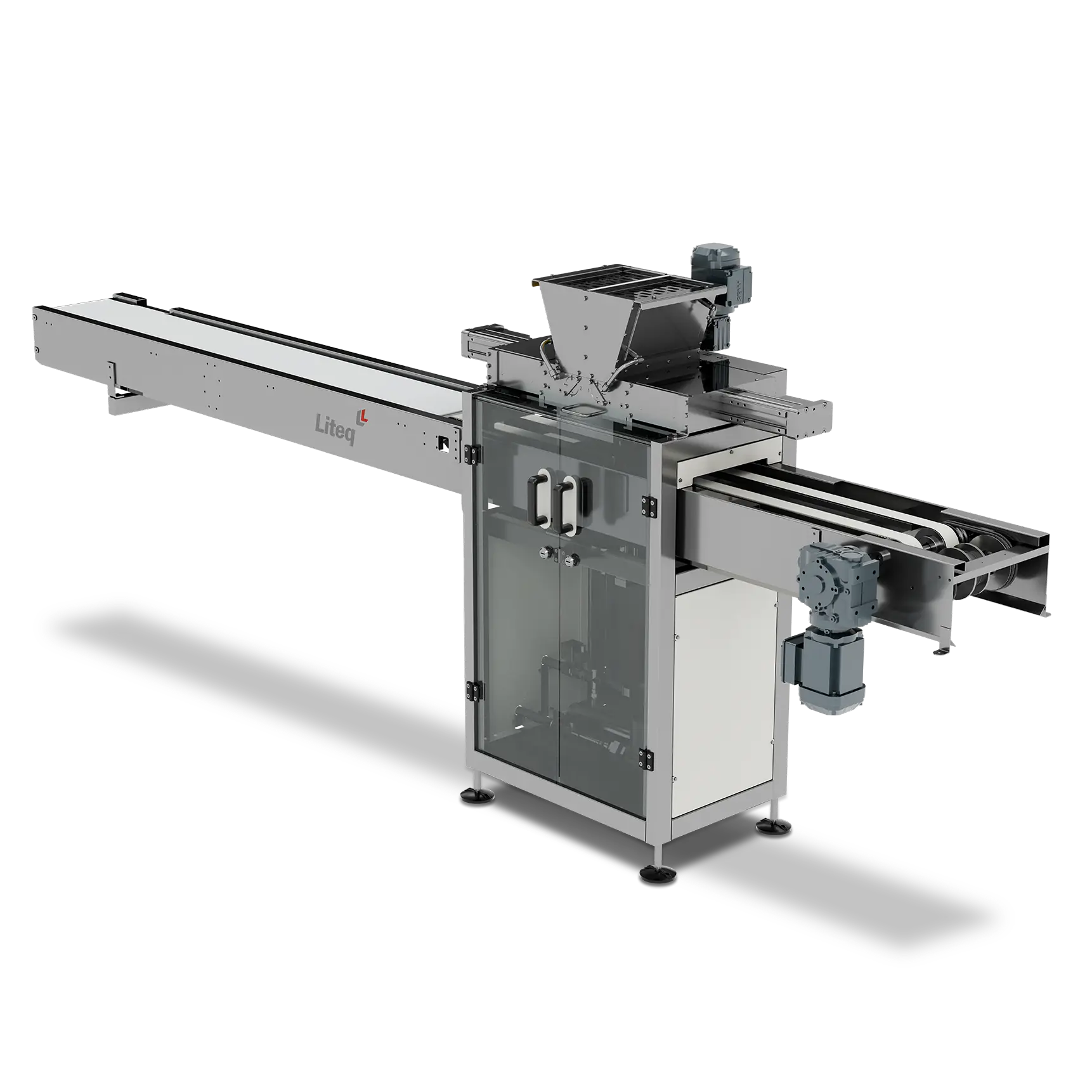

Cutting Stations (longitudinal and transverse)

Cutting Stations (longitudinal and transverse)

Longitudinal/Transversal Cutting Stations are equipment designed to cut dough mats, base

for cereal bars, nut bars, caramel bars (crunchy or soft), fondant bars, etc. and use

circular knives (longitudinal cut) and guillotine knives (transversal cut).

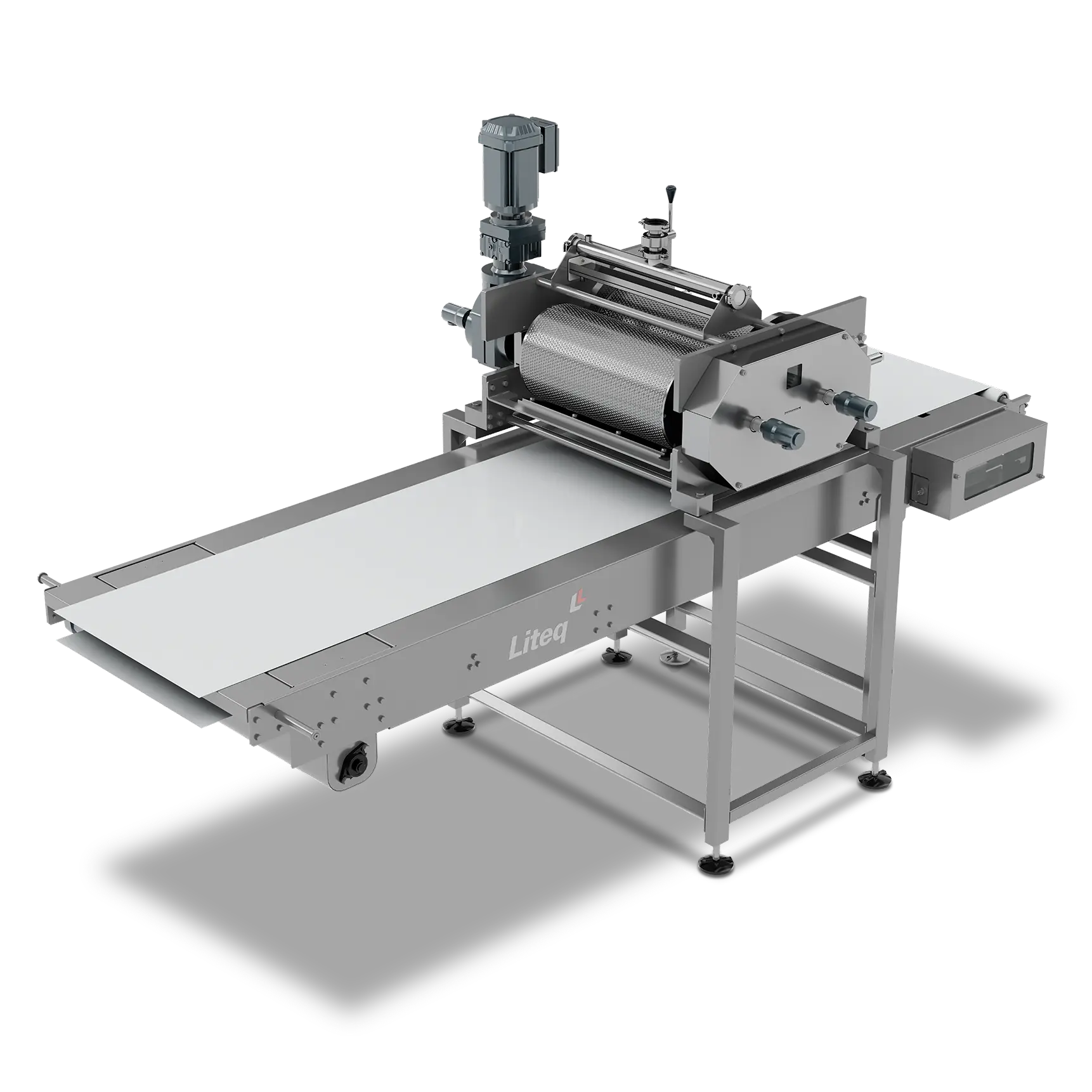

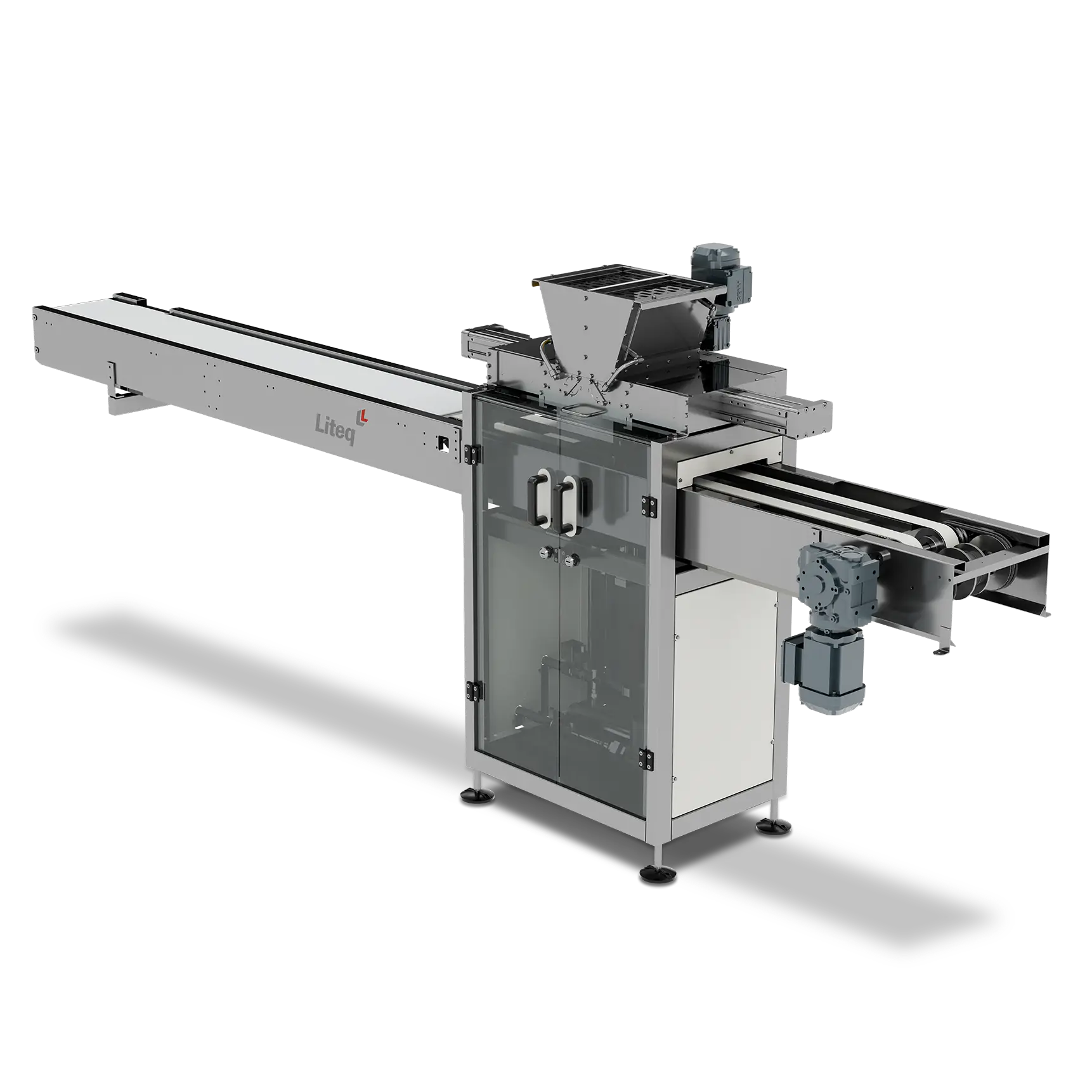

Enrobing T-Cober

The ideal solution for precise and efficient coating of chocolates and pastries

The LITEQ enrobing, models Compact (500 and 700) and Master (620 to 1800), offer high quality coating in small spaces or large production runs. For chocolate and similar compound doughs, they are extremely economical and versatile machines designed to apply a thin layer of chocolate to filling bars and chocolates, cereal bars, protein bars, seed bars, cookies, wafers and more...

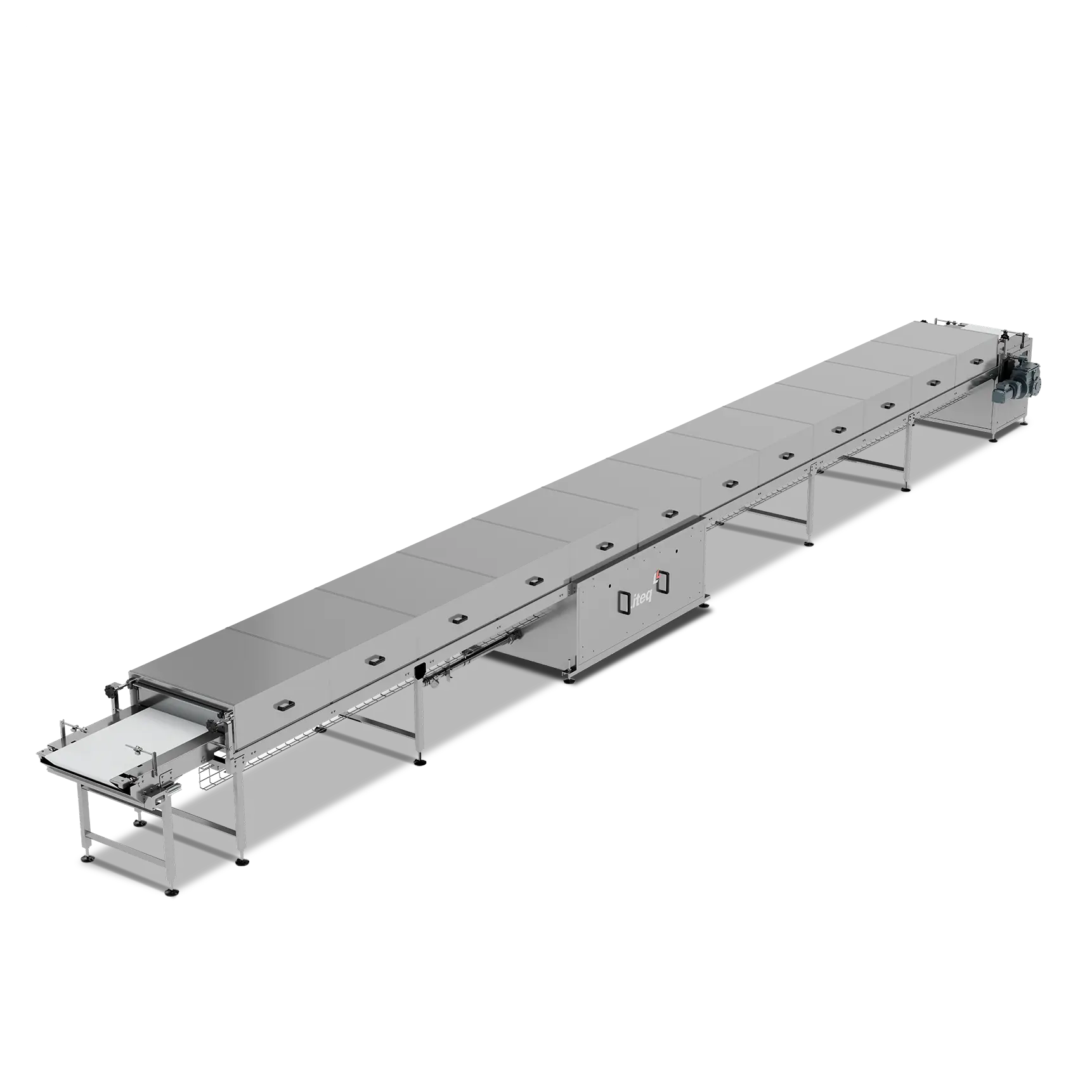

Cooling

Cooling

Complementary equipment

Complementary equipment for chocolate, confectionery and cooling lines

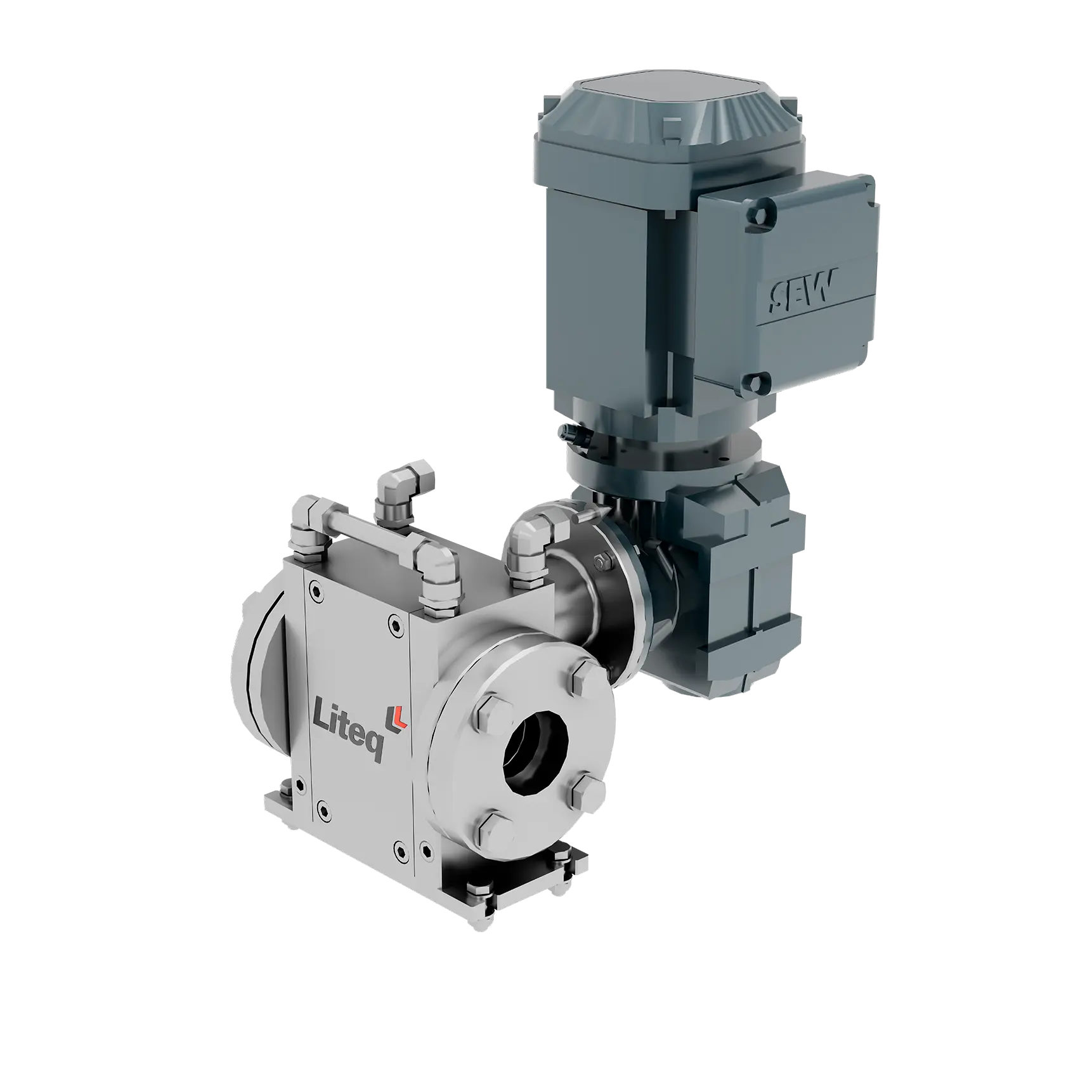

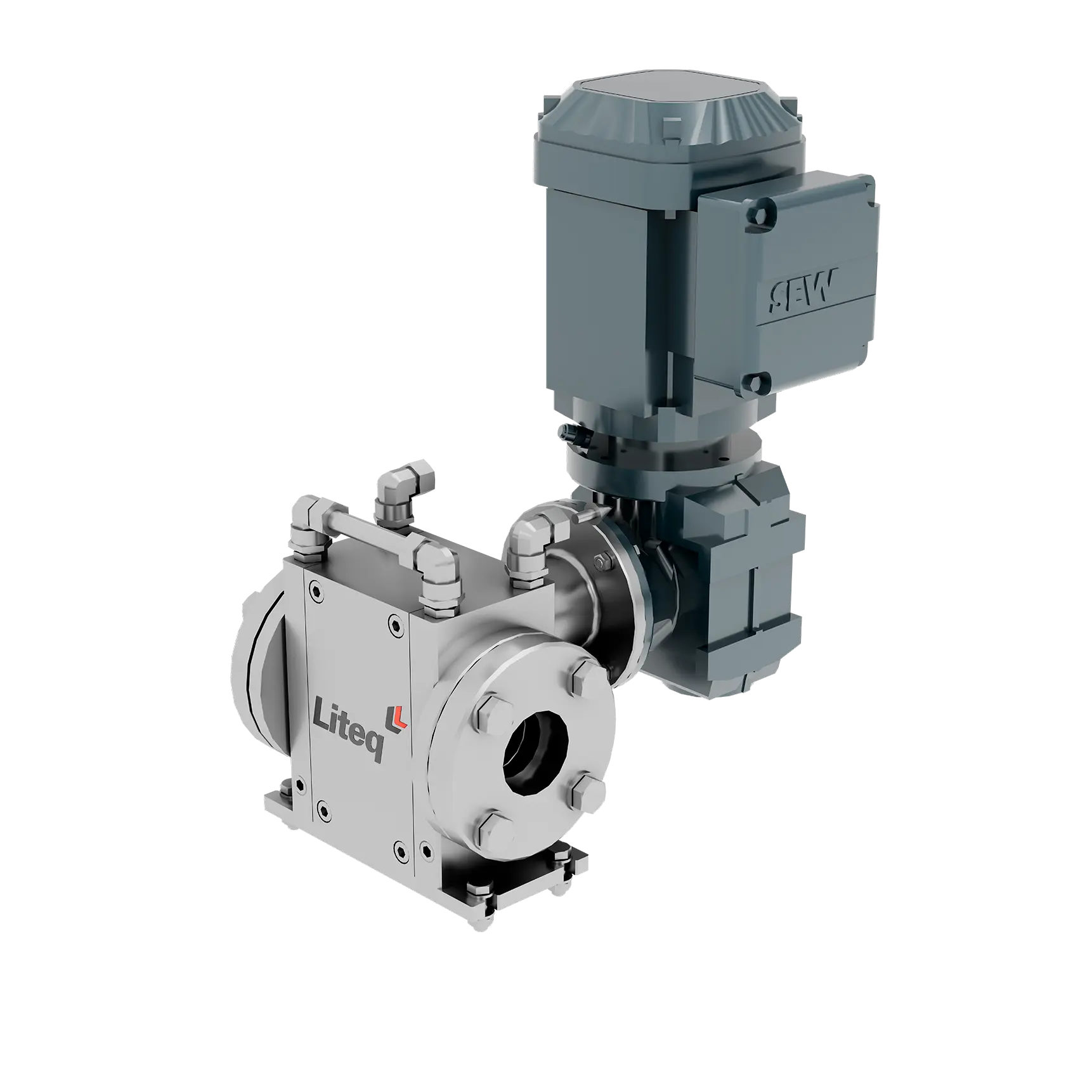

Positive pumps

Chocolate

Liteq's positive pumps are extremely simple and robust pieces of equipment, whose design (parallel tooth gear or rotating clutch) guarantees great efficiency and low maintenance costs. They can pump from 500 to 10,000 kg/h of chocolate or similar products.

Continuous Liquid Dosing and Dynamic Mixing System

T-Mixer

The "T-MIXER" dynamic liquid dosing and mixing system has been developed to provide the homogeneous mixing of liquids, always in a continuous manner, and being able to work with the most varied types of products, such as creams, chocolates, syrups, among others, and it also has a flavoring/colorant container. is equipped with a dosing pump.

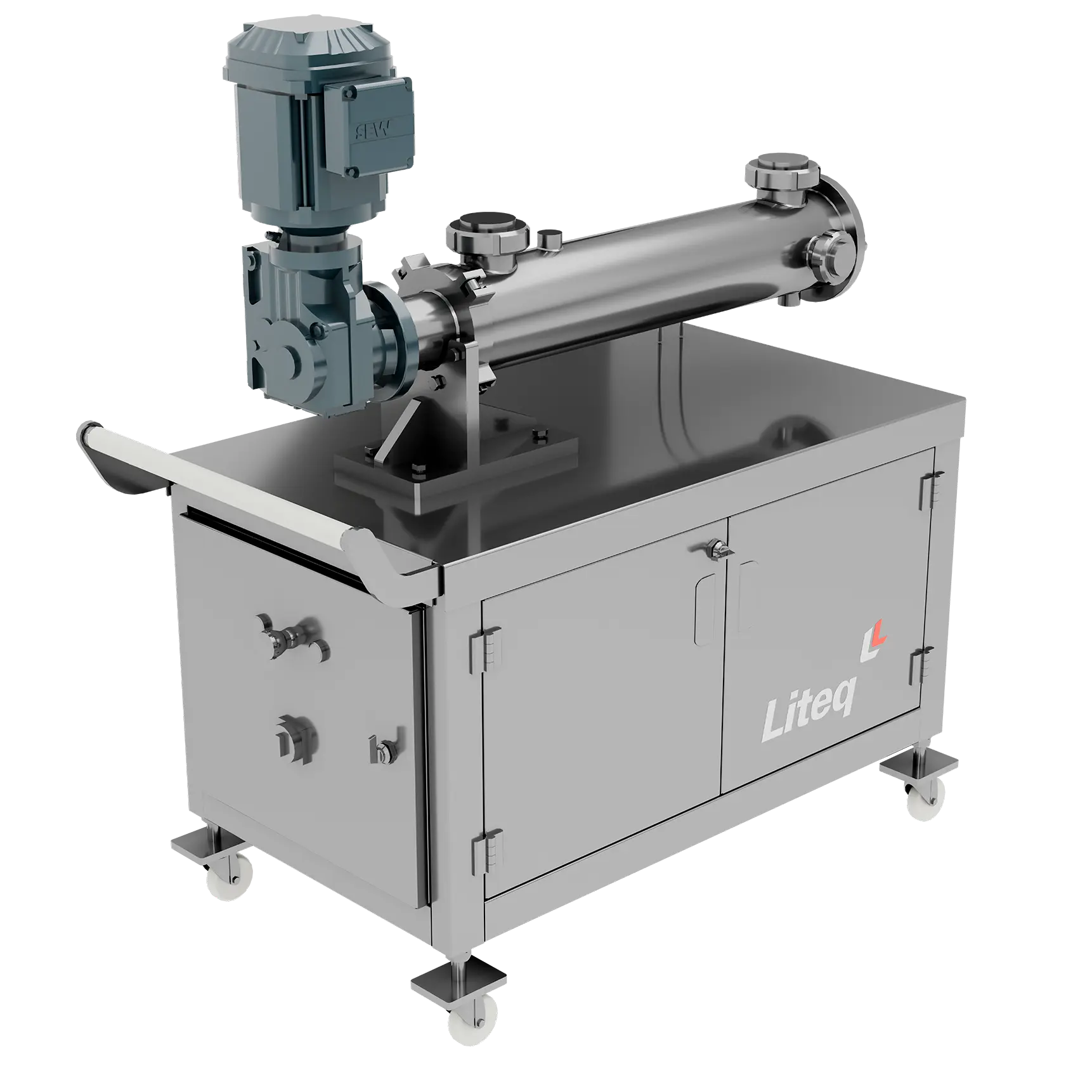

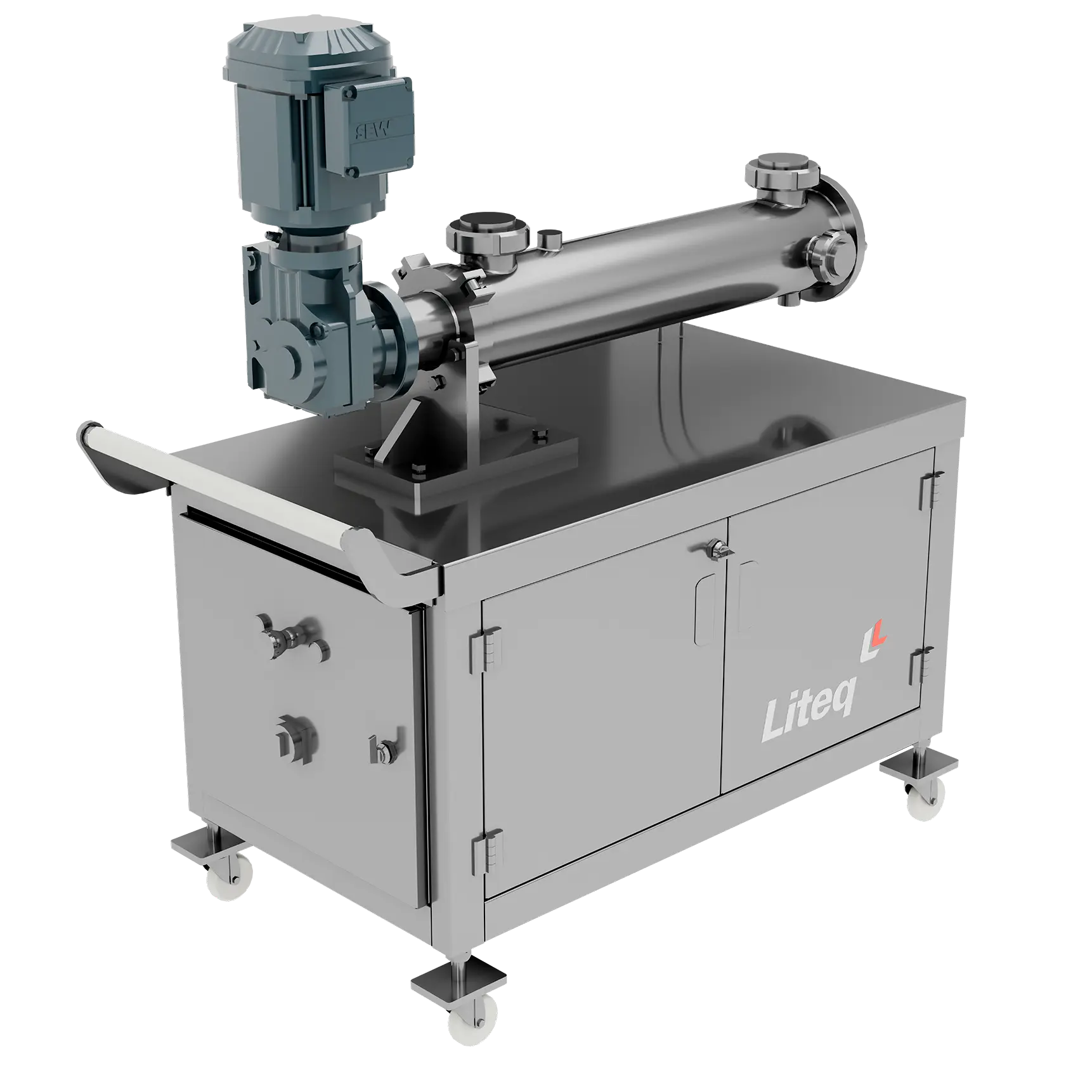

Heat Exchanger/Decrystallizer

This exchanger is fitted with connections and pipes jacketed in a bidirectional circuit, through which hot water passes externally and chocolate on the inside of the pipe. The chocolate passes through the pipe with a turbulent flow to increase the efficiency of heat exchange in the system. The exchanger is manufactured in such a way that it can be completely dismantled for easy cleaning.

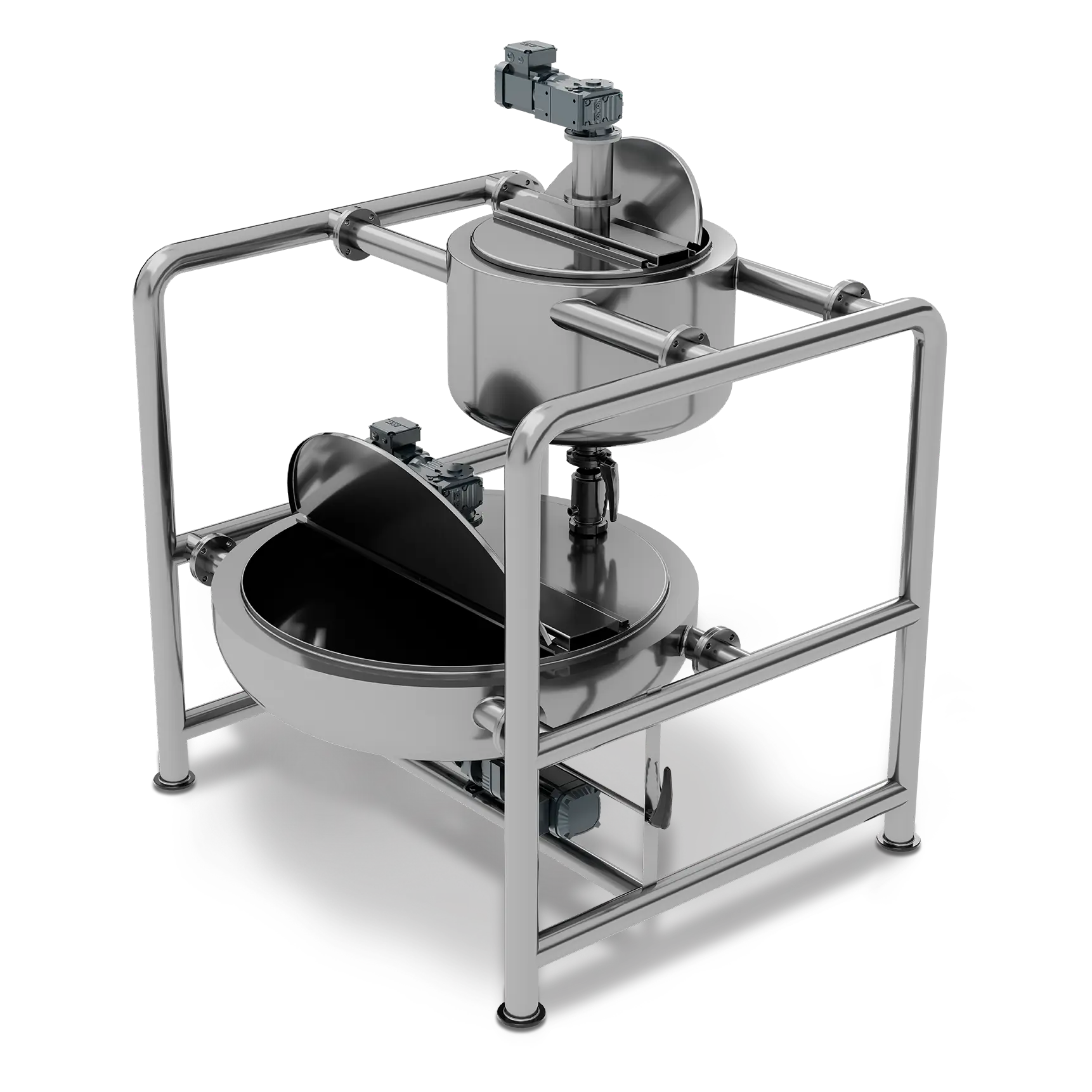

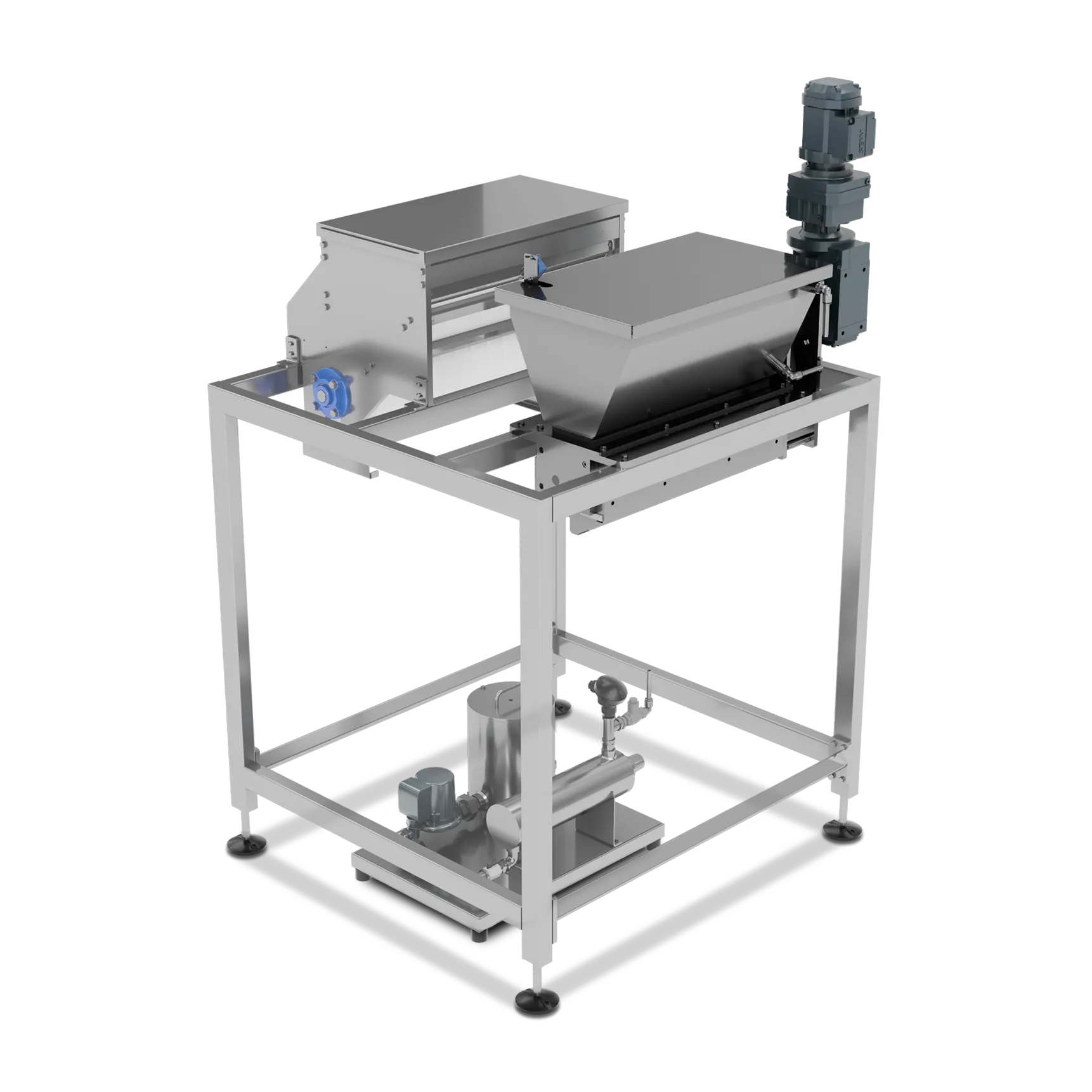

Ingredient mixers

High viscosity

This equipment has been developed to provide perfect homogenization of a mixture made up of solids and liquids, whether hot or cold. They can be used to mix cereals, crystal sugar, raisins, seeds, rice crisps, cornflakes, etc. with a hot or cold liquid. One of the great advantages of this equipment is the low percentage of ingredient breakage during the mixing process.

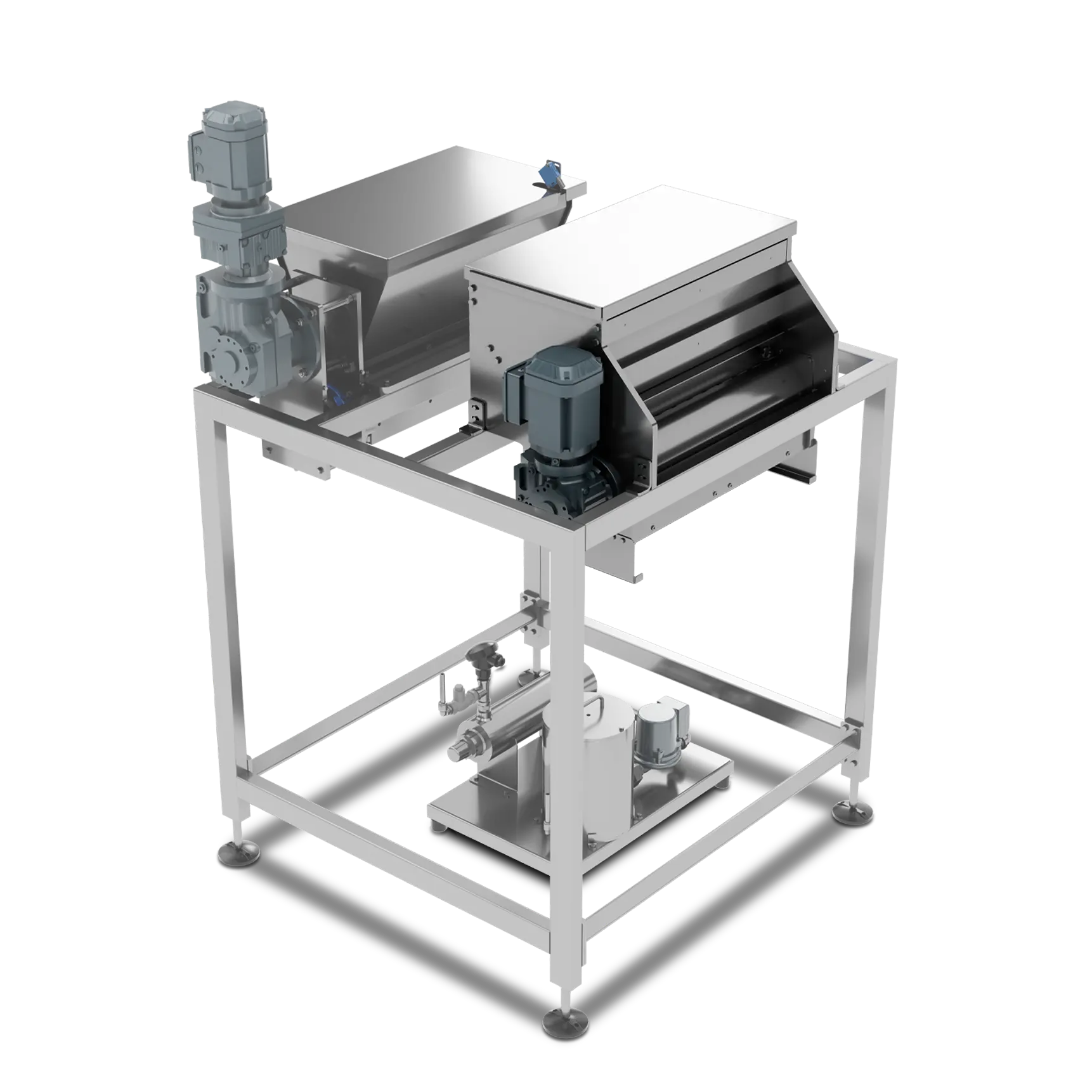

Ingredient mixers

Low viscosity

This machinery was developed to provide a perfect homogenization of a mixture formed by solids and liquids, hot or cold. This equipment can be used to mix cereals, raisins, seeds, “rice crisps”, corn flakes, etc. a liquid and has as its great differential, the low percentage of breakdown of the ingredients during the mixing process.

Special projects for product handling/conveyors

Developed according to the needs of each client

Special Projects for Product Handling are pieces of equipment developed according to the needs of each client, in order to optimize the use of the production area and reduce the manpower involved in the process. This equipment is ideal for companies that have excessively manual or discontinuous manufacturing processes.

Decorating Machine

Decorate the products with chocolate fillets or similar paste

The purpose of this equipment is to decorate products with chocolate fillets or similar mass on top. The great advantage of Liteq's decorator is the nozzle pressurization system, as there is a mini gear pump for each set of 4 nozzles, which significantly reduces clogging

of these.

Chocolate

/ Liquor / Fat Melter

The liquor/fat/chocolate melter has been developed to optimize the process of melting liquor, chocolate or similar fat into blocks or kibbles, turning this operation into a continuous and safe action.