versatile for

candy coating

Versatile for

candy coating

Optimize your production

Enrobing T-Cober

Enrobing T-Cober

The LITEQ Coverers, Compact (500 and 700) and Master (620 to 1800) models, offer high quality coverage in small spaces or large production runs. The Compact line is ideal for small areas, with up to 4 m/min and the option of a tempering machine on the 500 model. The Master line offers a robust structure, easy operation and speeds of up to 12 m/min.

Optimize your production

Enrobing T-Cober

Enrobing T-Cober

The LITEQ enrobingThe Compact (500 and 700) and Master (620 to 1800) models offer high-quality coverage in small spaces or large production runs. The Compact line is ideal for small areas, with speeds of up to 4 m/min and the option of a tempering machine on the 500 model. The Master line offers a robust structure, easy operation and speeds of up to 12 m/min.

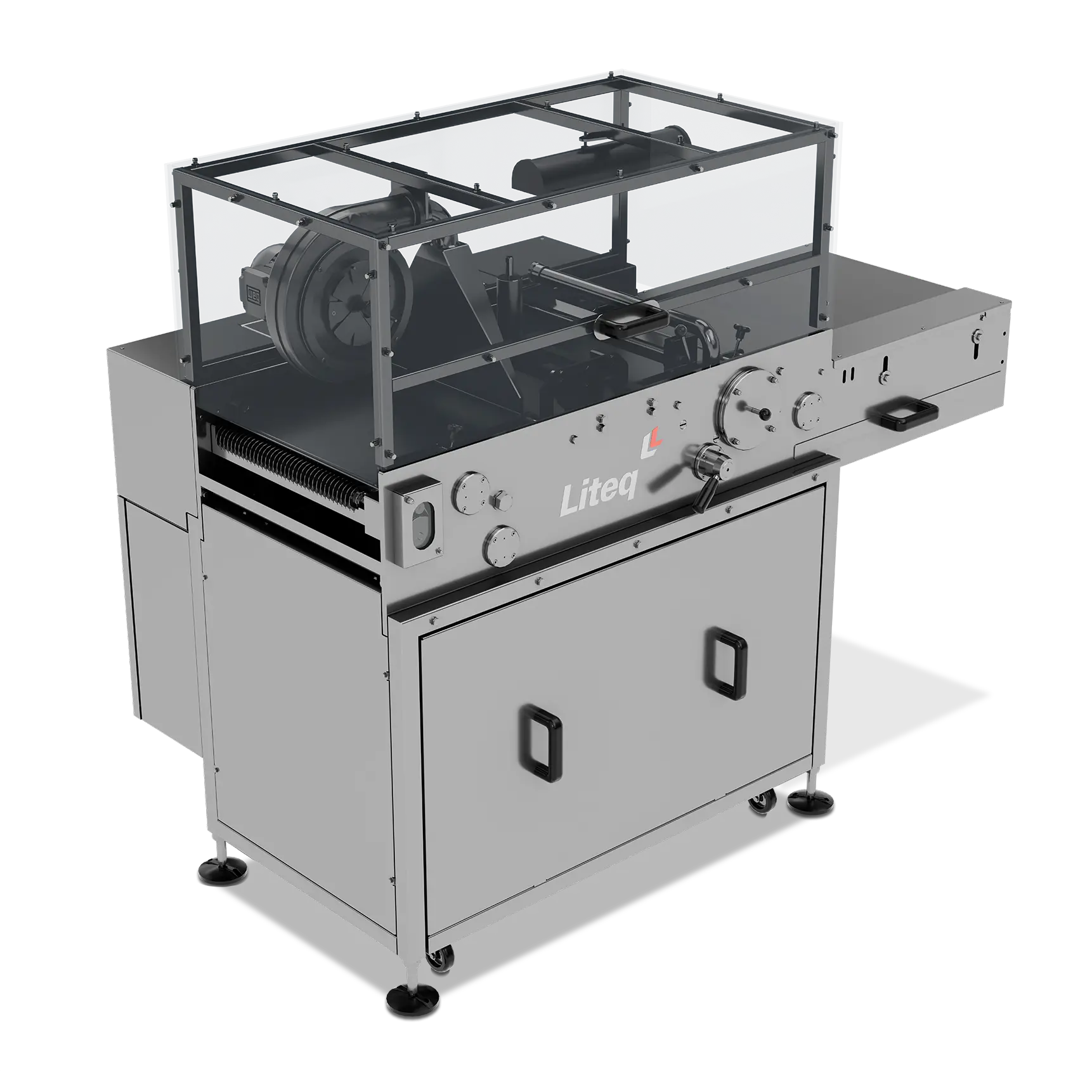

COMPACT MODEL

COMPACT ENROBING MACHINES

Technical details

The COMPACT MODEL MATS, 500 and 700, are part of the Compact Line LITEQ. This line has been designed to allow production with the same quality and efficiency, but can be installed in reduced spaces and at an excellent cost-benefit ratio. With conveyor/covering speeds of up to 4m/min, the COMPACT COVERS come in widths of 500 or 700 mm and have all the necessary components to provide quality covering. On the 500 model, the machine can be equipped with a built-in tempering machine, making it possible to cover with chocolate.

MASTER MODEL

Enrobing T-Cober Master

Technical details

LITEQ’s enrobing machine for chocolate or compound is an extremely economical and versatile equipment, developed with the purpose of applying a thin layer of mass on filling bars, cereal bars, seed bars, cookies, among others. Our latest model was developed with the intention of adapting to the most modern concepts of hygienic engineering and easy operation (easy maneuver, easy setup, easy inspection, easy maintenance and easy cleaning), which is now the main distinguishing factor of our equipment compared to other products currently in the market. Our equipment was developed to work with speeds up to 10m / min and with widths between 620 and 1.800 mm.

Want optimize your production?

Contact our technicians