Setup

fast

Setup

fast

Optimize your production

T-Mold Compact

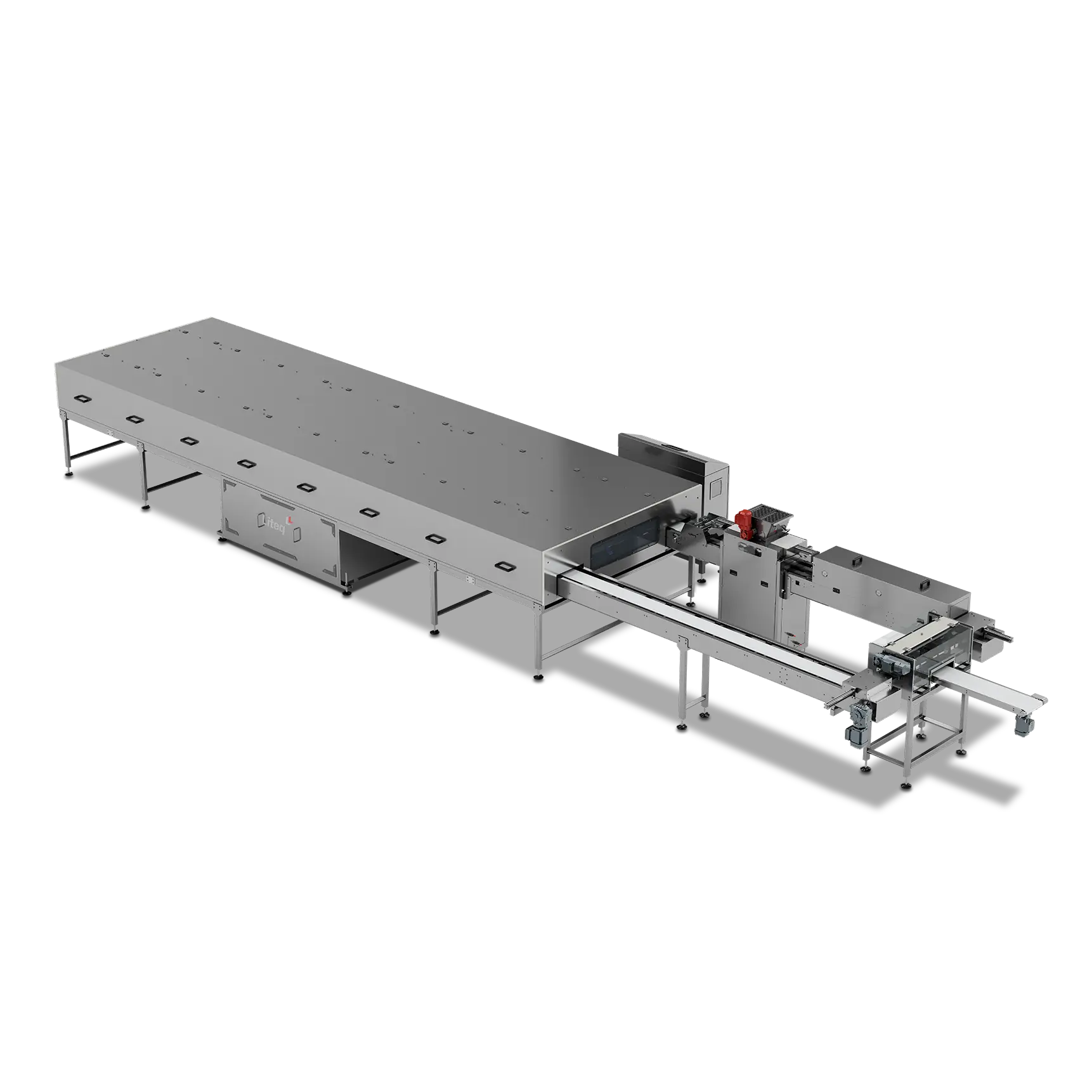

The automatic line includes dosing, vibration, cooling tunnel, demolding and reheating of molds. Produces up to 15 molds per minute without labor, with fast and flexible setup. It handles a wide variety of products with standard 275 x 175 mm or 300 x 300 mm molds.

Optimize your production

T-Mold Compact

The automatic line includes dosing, vibration, cooling tunnel, demolding and reheating of molds. Produces up to 15 molds per minute without labor, with fast and flexible setup. It handles a wide variety of products with standard 275 x 175 mm or 300 x 300 mm molds.

Technical details

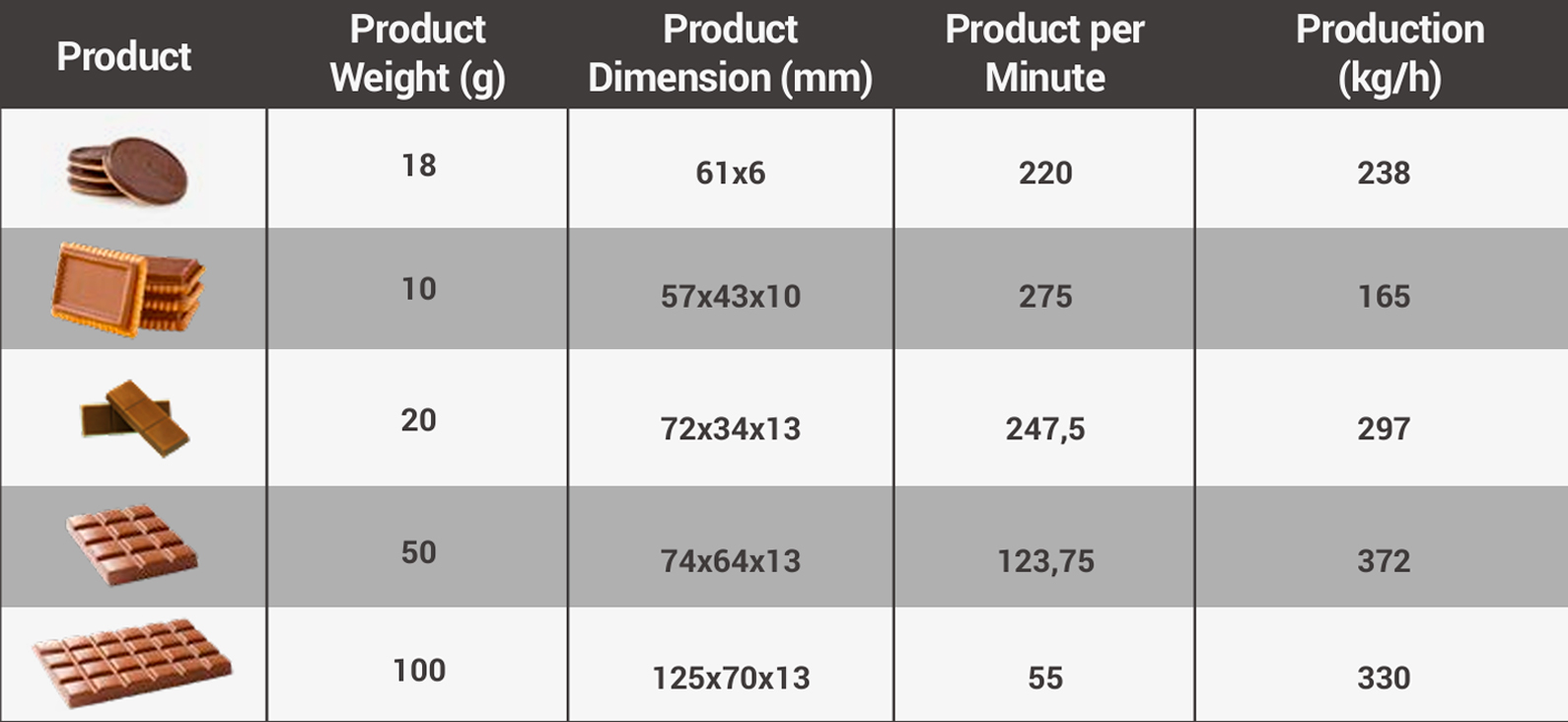

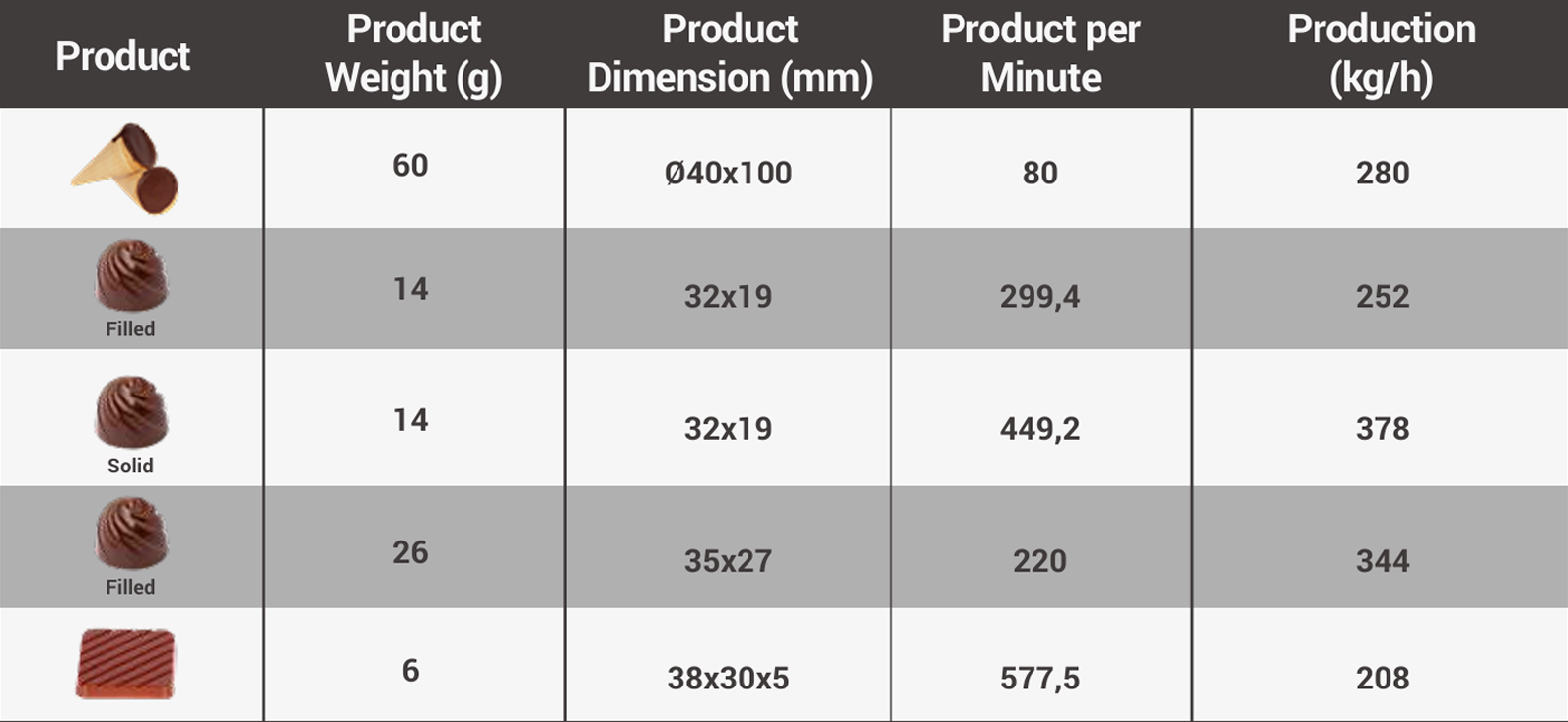

Composed of a Doser, Vibrating System, Cooling Tunnel, Automatic Unmolding System and Mold Reheating System. The equipment allows the automatic production up to 15 product molds per minute, without the use of labor. With a flexible design and fast setup, we guarantee a wide variety of products, meeting the highest quality standards. Below we can see some of the products and production capacity with the standard molds 275 x 175 mm or 300 x 300 mm, used in the production of molded chocolates with biscuits.

TABLES

Want optimize your production?

Contact our technicians