Precision in

chocolate dosage

precision in

chocolate dosage

Optimize your production

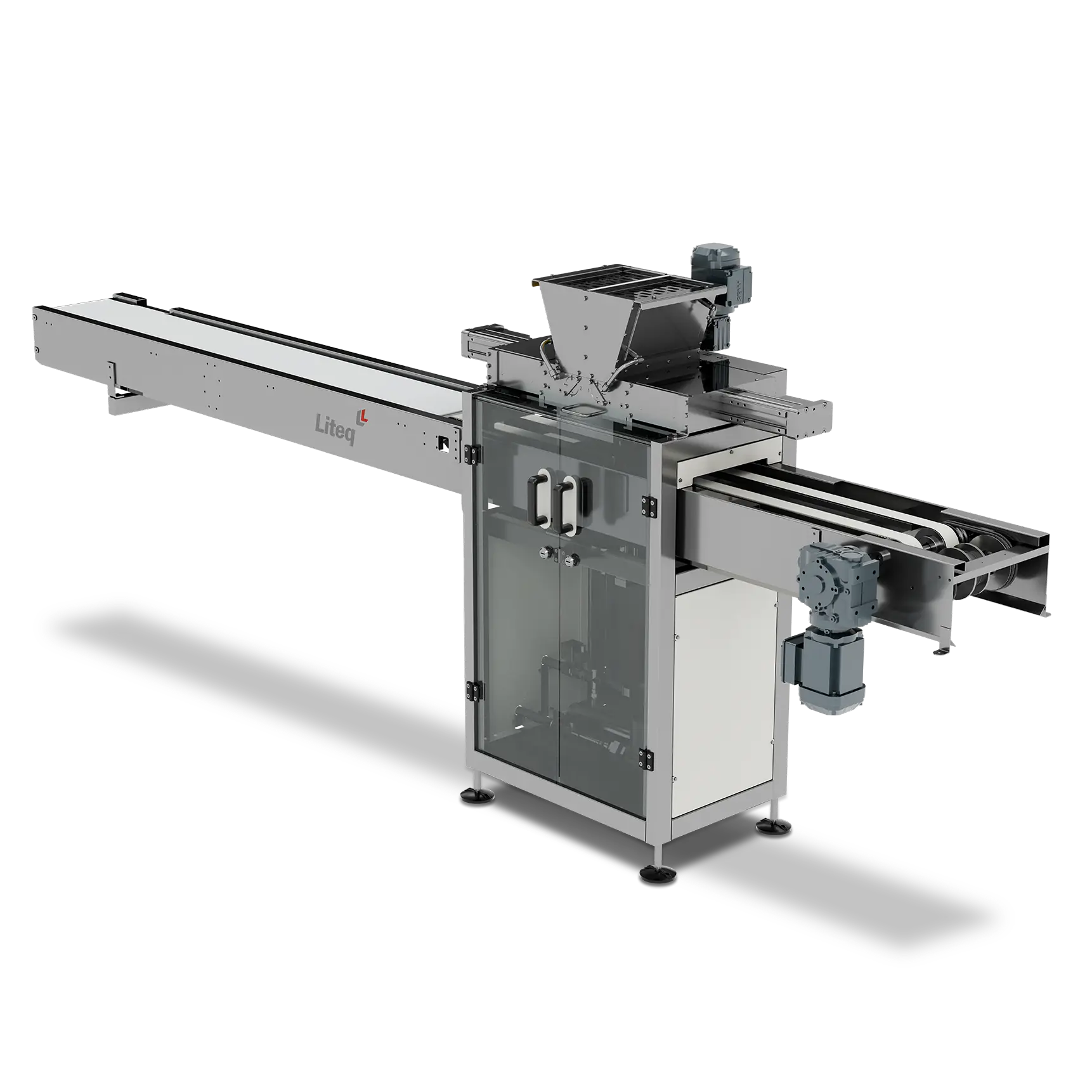

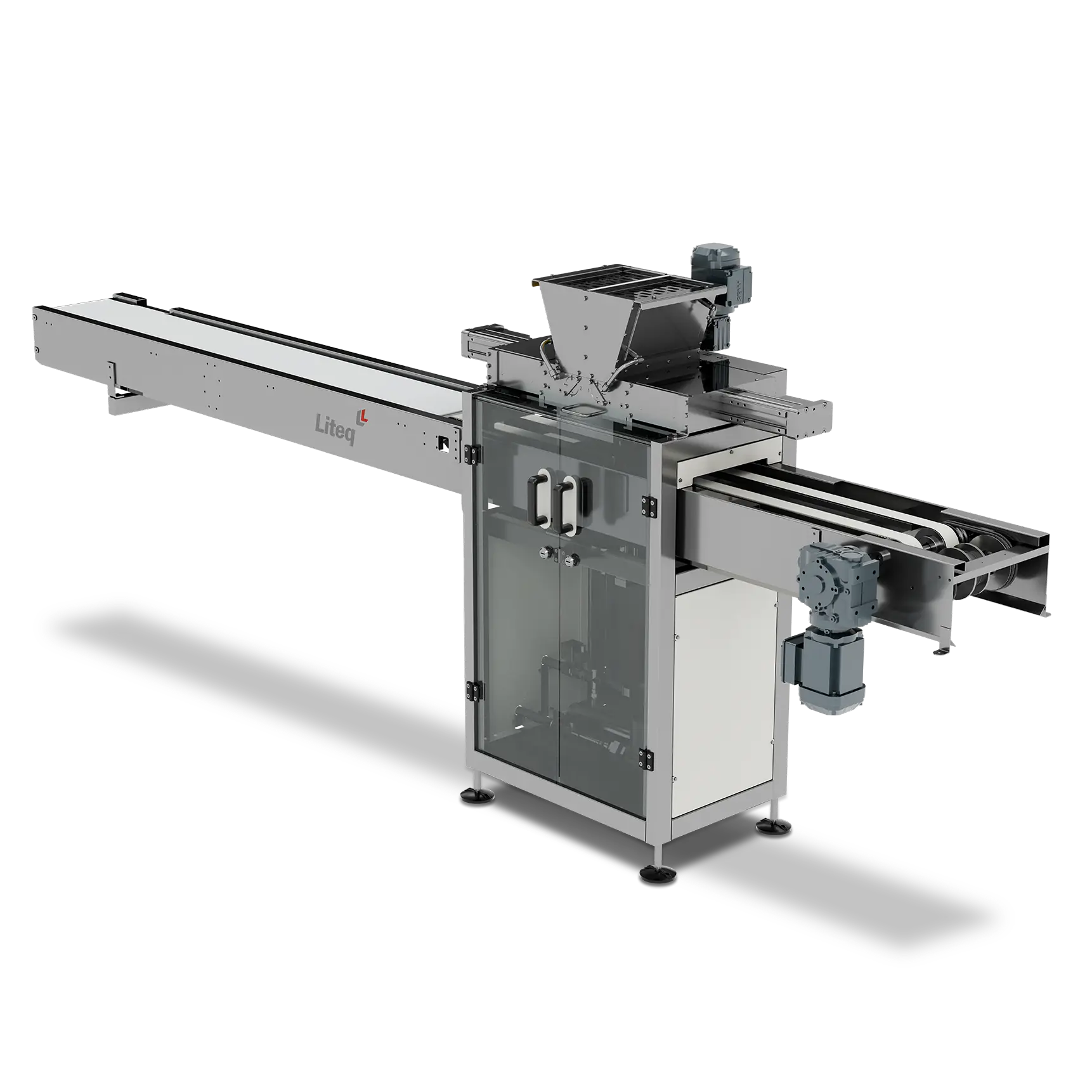

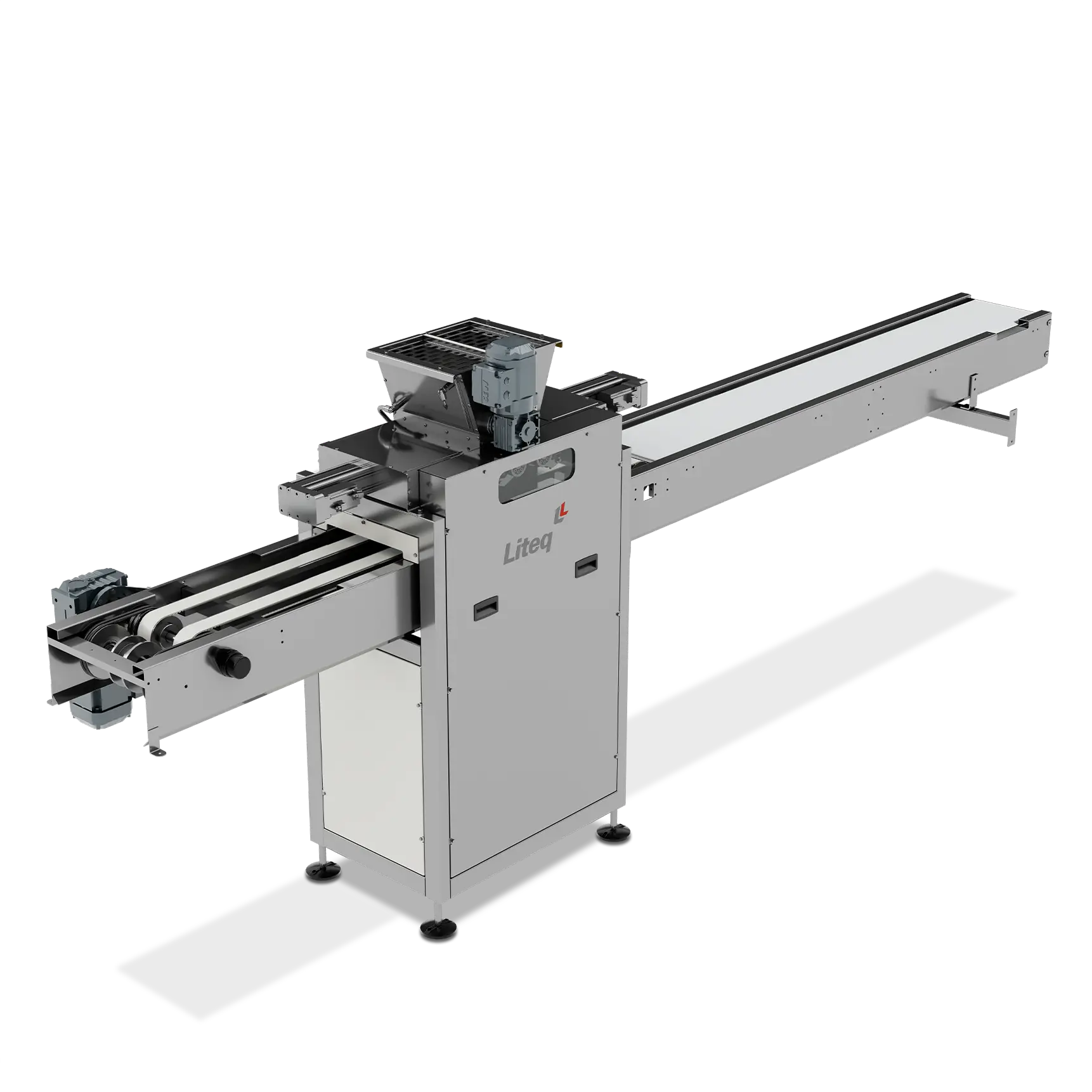

Piston chocolate depositor

This Piston Chocolate Depositor is an extremely versatile and precise machine, designed to work with the one-shot, point or "tongue" dosing system, which allows it to be used for dosing solid tablets with or without additions, filled chocolates and Easter eggs.

Optimize your production

Piston chocolate depositor

The Piston Chocolate Depositor is an extremely versatile and precise piece of equipment, designed to work with the one-shot, point or "tongue" dosing system, which allows it to be used for dosing solid tablets with or without additions, filled chocolates and Easter eggs.

Technical details

The piston chocolate depositor is an extremely versatile and precise equipment, designed to work in intermittent dosing function. The point and one shot system allows the dosage of tablets (with or without fillings), chocolate cadies and Easter eggs. In this Depositor model, the mass intake, dosing and suction movements are controlled via power-assisted motors, which allows a high control over the chocolate dosage / filling, ensuring great precision in the control of the net weight of the final product. The equipment can work with single, one shot and tongue dosage.

Want optimize your production?

Contact our technicians